CLIENT AOUC, Florence

DESIGN TENDER 1st prize

ARCHITECTURE Ipostudio; Elio Di Franco; CSPE

STRUCTURE Gipieffe architettura; aei progetti

MEP Consilium; CMZ; Lombardini Engineering

DESIGN 1999-2006

REALIZATION 2006-2010

AREA 42.900 sqm

TOTAL COST 24,2 mio €

STRUCTURE COST 5,2 mio €

The area of the intervention is at the north of the sanitary complex and represents both the ‘scenic interface’ with the city and the ‘entrance door’ to the Hospital Campus. Such area is organized on the basis of a real ‘ordering will’, namely the one of a real urban area following the morphological and perspective profile characterizing the urban structure of the city. Architectural choices concern the both functional organization and urban characteristic of the intervention that foresees 4 u.g. and. a.g. floors. A large roof supported by thin steel columns both partially and totally covers several blocks, hence becoming the compositional and functional barycentre of the whole system.

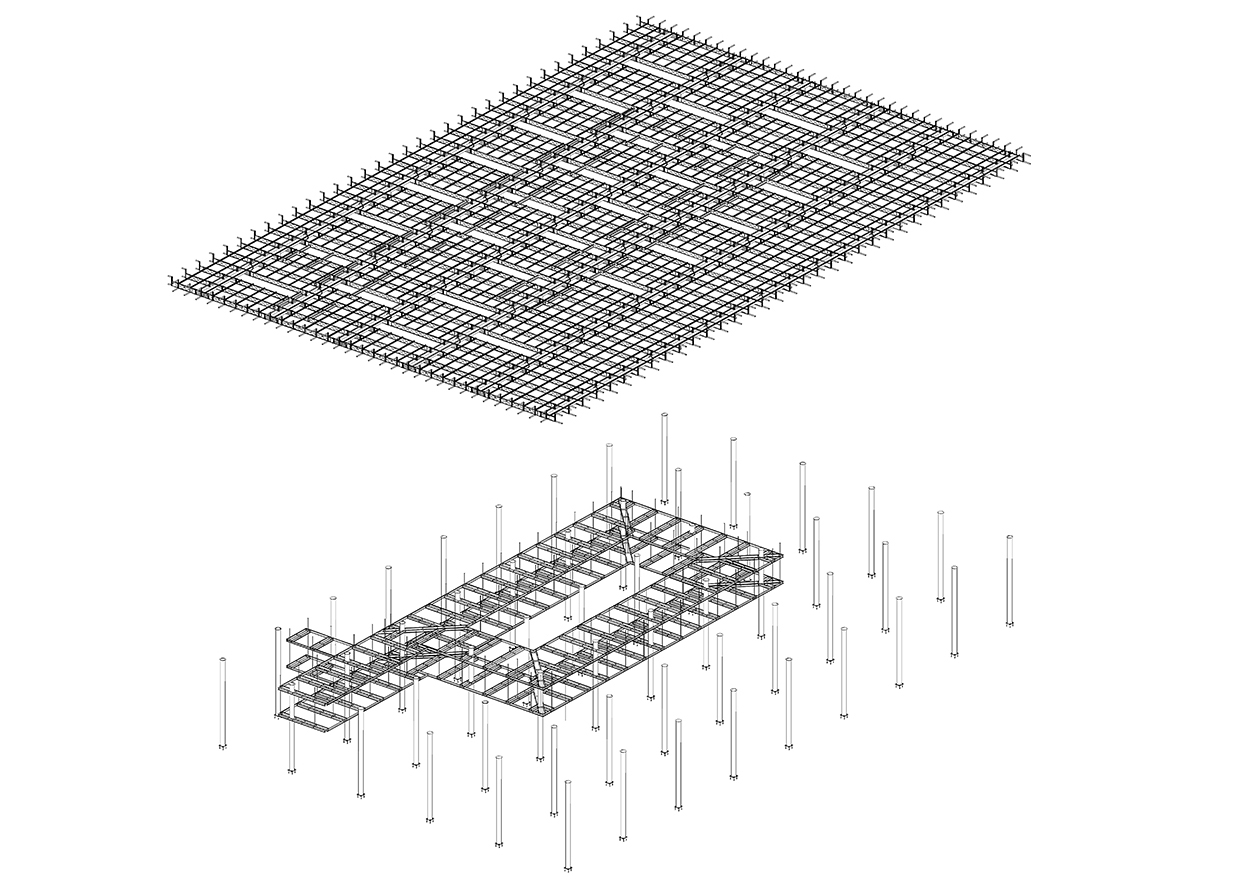

It is the double-height entrance hall: a transparent envelope that allows the user to have an outside-inside view of the activities when accessing the Hospital, and vice versa enables him to understand his own position in relation to the big covered square, when inside. Some convention room and a ‘bridge’ connection with the west office-block are over the Hall. The full-steel structure of the covered square is peculiar for its simplicity, aim of a careful study during the project realization. The alignment of empty circular columns on a 10.8×10.8 m mesh, supports a row of circular main beams where double-T secondary beams rest in a perpendicular way and are in turn the support for the third row of elements where both upper and lower roof panels are placed.

Such a structural hierarchy extends to the architectural solution for supporting the ring volume bordering the internal part of the square: an air-volume partially resting on circular columns and partially suspended from the roof structure by means of circular small-section rods. The typology of joints requires the welding in the workshop both of the top-part of the pillars to main-beams’ abutments and of the main beams to the secondary elements’ chunks. Such typology therefore enables to move bolted-on-site joints to less stressed sections hence significantly lightening the joints and, at the same time, stiffening and connecting the junctions where all structural elements converge. The continuity of critical junctions and the typology of sections gives the two-way frame construction a high resistance both to wind horizontal actions and to seismic actions despite the lack of bracing elements: the dissipation of seismic energy is entrusted to the structure’s post-elastic resources.